Manufacturing

Time Variances

Manufacturing

Time Variances Manufacturing

Time Variances

Manufacturing

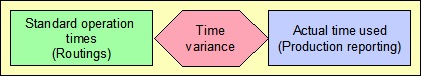

Time VariancesThe time variances for machine time, setup labor time and direct labor time come from the difference between theoretical times defined in the routings and the actual times used.

The actual manufacturing times are entered by the Production reporting function. Using this function, it is also possible to enter the quantities of good parts (i.e. the parts satisfying the required quality level), of rejected parts and the machine and direct labor used hours.

The actual machine and labor hours used are recorded in the work order. Furthermore, on this work order operation record, the successive updates can be followed.

It is worth recalling that production reports are allowed exclusively for count point operations. The operations that are not at count points are assumed to be realized as soon as the previous operation is finished, without any production report. By convention, one assumes that the operation times for operations without a count point are always the standard routing times.

Valuation of manufacturing time variances

According to the principle of standard costs accounting, the variances of manufacturing times (machine and direct labor) must be valued by using ‘machine hour’ and ‘labor hour’ standard costs.

The comparison is made between the actual hours used (stemming from the production reports) and the standard times (that are given in the routings used).

Hourly machine and/or labor rates are defined for each cost center. Therefore, for a particular operation in a work center, the rate of the corresponding cost center is used.

For a given work order, the manufacturing time variances are equal to the sum of the variances for the operations of the bill of operations.

The variances for machine time and for direct labor time for an operation are calculated as follows:

(used hours – standard hours) x hourly rate for the cost center.