Planning BOM

Planning BOM Planning BOM

Planning BOM

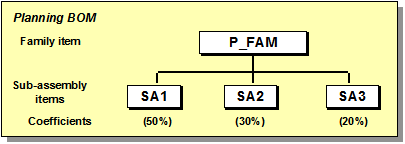

The planning bill of material permits disaggregating the family item projected inventories (the S&Op Plan menu) into items projected inventories (also called Internal requirements in the Master schedule window).

When producing to order, the planning bom permits disaggregating the family item projected inventories (the S&Op Plan menu) into finished items projected inventories. On the contrary, when producing under an assembly-to-order logic, one specifies in the planning bom the decomposition of the family items into the intermediate items used in the assembly process. In this case, using the S&Op Plan Disaggregation function, intermediate items projected inventories are established, in such a way that customer orders for the finished products can be assembled with a short lead-time.

It is important noting that one can define for each link a validity time period. In this way, it is possible to define commercial bom links that evolve along time. For example, if the coefficient for SA1 is expected to be equal to 50% in 2004 and 45% in 2005, two links are created: a 50% link valid from 01/01/2004 to 12/31/2004 and a 45% link valid from 01/01/2005 to 12/31/2005.