Material Usage

Variances

Material Usage

Variances Material Usage

Variances

Material Usage

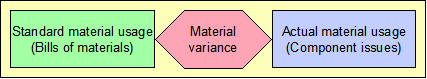

VariancesThe material usage variances are equal to the differences between what should have been used, according to the data in the bill of materials, and what was really used.

The function WO component issues (from the Control menu) permits one to enter information about actual usage.

The differences in material usage may come from extra requirements (or possibly from reduced requirements) with respect to the theoretical usage define in the bill of materials.

The theoretically required components necessary to manufacture a given quantity of items in a work order can be released using the Auto issues function.

However, if an extra requirement arises, a new part release must be entered. The function Issue by line is used and the line number and release quantity have to be entered.

Inversely, if fewer parts or less material than issued are required, the surplus must be returned to inventory. The surplus return can be entered by executing a release by line and entering a negative release quantity.

The inventory transactions related to a given work order are recorded in the bill of materials links of the work order.

It is thus possible to compare the quantities that theoretically should have been used with those that were actually consumed.

Valuation of material variances

According to the principle of standard costs in accounting, the variances of material consumption are valued by using the standard cost of the item. The value of the material variance of a component is therefore equal to:

(Standard consumption – actual consumption) x Standard cost

Consumption variances are linked to the fabrication process.

The buying price variances (the difference between the price actually paid to the vendor and the standard buying price) are not linked to the cost of manufactured products.