Principles of Distribution

Management

Principles of Distribution

Management Principles of Distribution

Management

Principles of Distribution

Management

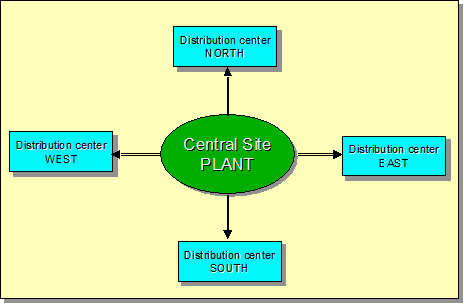

From a global viewpoint, sales of the products can be delivered from the plant’s finished products distribution center but also from several distribution centers, which are strategically situated near important market segments. These distribution centers preserve stocks which are restocked from the central site. The functions of distribution management are accessible only if the Distribution function is activated in the Preferences window.

In the first step, the company makes sales forecasts for each distribution center (it is worth noting that the customers are attached to the different distribution centers). These forecasted sales have to be delivered from the distribution centers, which induces the necessary replenishment orders which are to be delivered from the plant to each distribution center.

When the available inventory in a distribution center is considered too low in order to satisfy the future customer sales, a delivery request is sent to the central site. These delivery requests are computed according to the inventory policy of the distribution center.

These requirements from the distribution centers are treated as internal needs (which enter into the net requirements calculation procedure at the plant level, also called the MRP procedure in the Planning menu).

The manufactured products are transported to the distribution centers from where they can be delivered to the customers.

It is interesting to have two approaches:

•a global point a view, from the central site,

•local points of view, from each distribution center.

From the central site viewpoint, one has a global vision of the requirements and inventories of the entire system. One can manage production and restocking of the distribution centers according to the needs expressed.

From the distribution center viewpoint, one is interested in local information, local flow management from the plant and delivery procedure to local customers.