Resource BOM

Resource BOM Resource BOM

Resource BOM

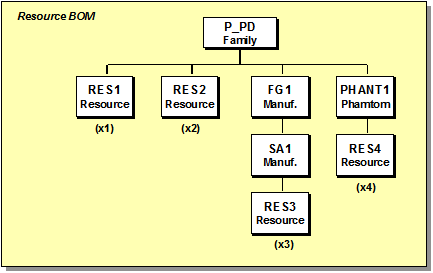

The Resource bill of material indicates how much critical resource capacity is necessary to produce one unit of a family item. In this way, the loads calculation is possible for a given production plan for the different family items.

As depicted above, the link between a family item and a resource item can be direct (for RES1 for example), using another item (Res 2 for example) or using a phantom item (as Res3).

As for the classical BOMs, it is necessary, for each critical resource, to enter both the unitary consumption of resource by the family item and also the delay, positive or negative, between the consumption of the resource and the production plan date of the family item. Let’s consider the following example.

If the production of an item requires half an hour of labor in the assembly workshop, a link between this item and the labor of the assembly workshop resource is created in the Product Structure Record Maintenance window. The corresponding quantity required, 0.5 in this example, is entered in the Qty required field. If the resource consumption takes place on average 5 days after the release date, one indicates an offset of 5 in the corresponding field.