Routing Costs Calculation

Routing Costs Calculation Routing Costs Calculation

Routing Costs CalculationIn order to determine the costs of the routing, the following procedure must be followed:

•Define the budget lines in the budget lines table.

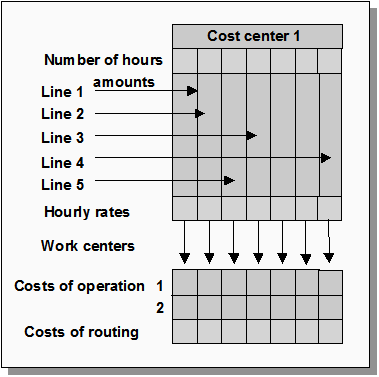

•Enter the totals of the budget lines for each cost center (Budget lines window), and the number of standard and simulated hours for machines and labor. This produces six budget costs and six simulated costs for each cost center.

•Specify for each work center the associated cost center.

•Define the routings. In particular, for each operation of a routing, specify the corresponding work center (the associated cost center is automatically found).

The routing costs are calculated for all the routings by the function Item costs Rollup from the Costing menu.

The calculation is done from the cost data entered in the Cost centers windows and from the operation and setup times that are detailed in the Operations windows, accessed via the Routings windows.

The calculation is done separately for each operation. The different types of costs associated to each operation are cumulated. Then, the costs of the different operations of the routing are added in order to get the routing costs.

From the work center’s cost center code, the seven hourly costs can be calculated:

•the Setup Labor Cost and the Direct Labor cost,

•the Shop Direct cost,

•the Economic depreciation cost,

•the Fiscal depreciation cost,

•the Sub-contracting cost,

•the Overhead on machine cost,

•the Overhead on labor cost.

Calculation Modes

|

Type of cost |

Fixed Costs |

Variable Costs |

|

Labor cost |

Is equal to setup labor time multiplied by the setup labor hourly rate. |

is equal to direct labor time multiplied by the direct labor hourly rate. |

|

Shop Direct cost |

Is equal to the machine setup time multiplied by the hourly shop direct cost rate. |

Is equal to the machine run time multiplied by the hourly shop direct cost rate. |

|

Fiscal depreciation |

Is equal to the machine setup time multiplied by the hourly fiscal depreciation rate. |

Is equal to the machine run time multiplied by the hourly fiscal depreciation rate. |

|

Economic depreciation |

Is equal to the machine setup time multiplied by the hourly economic depreciation rate. |

Is equal to the machine run time multiplied by the hourly economic depreciation rate. |

|

Sub-contracting |

Is equal to the machine setup time multiplied by the hourly sub-contracting rate. |

Is equal to the machine run time multiplied by the hourly sub-contracting rate. |

|

Overhead / Machine |

Is equal to the machine setup time multiplied by the hourly shop overhead costs rate. |

Is equal to the machine run time multiplied by the hourly shop overhead costs rate. |

|

Overhead / Labor |

Is equal to the machine setup time multiplied by the hourly labor overhead costs rate. |

Is equal to the machine run time multiplied by the hourly labor overhead costs rate. |